Integrated EtherCAT Controller

Flex-6 Nano Integrated EtherCAT Controller

P600 (2 Axis) | P601 (4 Axis) | P602 (8 Axis) | P603 (16 Axis) | P604 (32 Axis) | P605 (64 Axis)

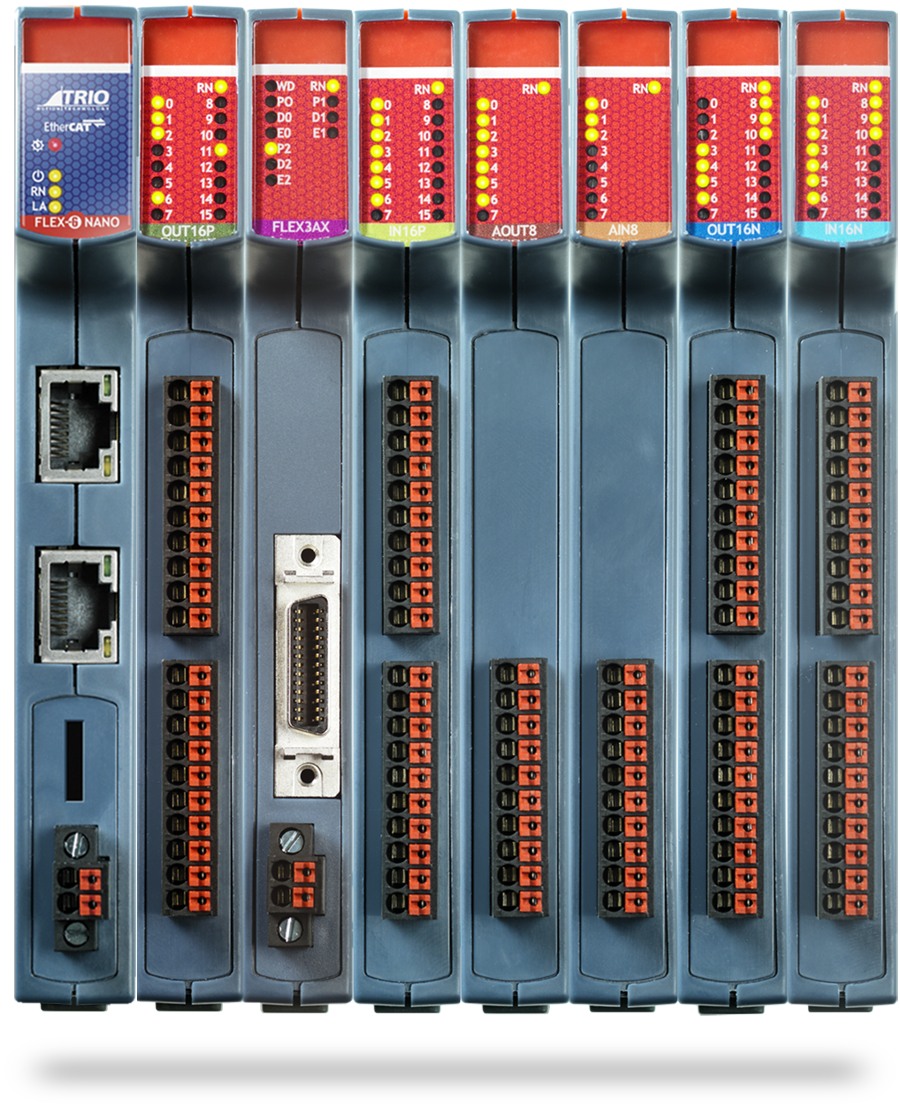

Powerful, compact and flexible, the Flex-6 Nano is an integrated EtherCAT solution offering up to 64 Axes of motion. It is expandable through the matching Flexslice range of Input, Output and Axis modules.

Highlights

- Dual core 1GHZ Arm Processor

- 2 - 64 Axes

- 1 GBit DDR3 Memory

- Memory can be Expanded with a Micro SD Card

- 1 GBit Fast Serial Flash Memory to Store Data Such as Programs, VRs and Tables

- Built in Retention RTC

- Built in EBUS Coupler for Direct Access to Trio’s Flexslice Slaves

- Cycle Time as Low as 125us!

- Field Programmable with Motion Perfect

- High Performance, Flexible Topology and Simple Configuration

- Bus Cycle Time Synchronised with Motion Coordinator Servo Period

- Ethercat Protocol to Individual Modules Using the EBUS System

- I/O Functions Tightly Synchronised to Motion Using Ethercat Distributed Clocks

- Practical Push-In Connector Options – No Break Out Required

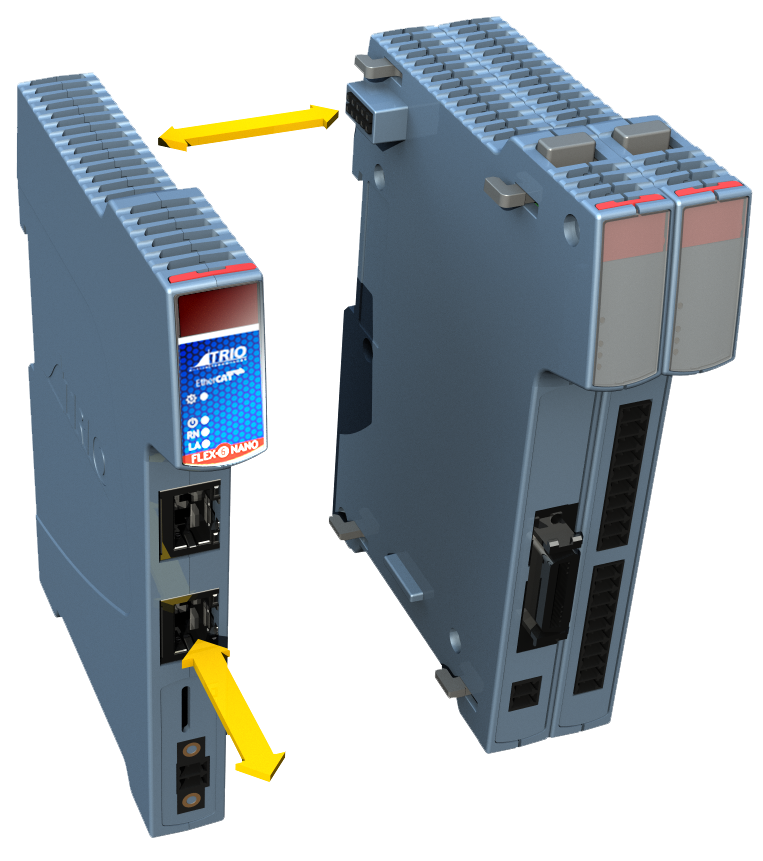

- Clip-Together Design With ‘Quick Release’ Locks For Mechanical Integrity

All in one Solution

The Flex-6 Nano is a powerful DIN rail mounted stand-alone flexible and compact Motion Coordinator. Its on board memory can be expanded to 32 GByte using a Micro SD card.

The Flex-6 Nano can be used as a stand-alone controller or can "plug" straight into our EtherCAT Flexslice System allowing expansion of the system to include servo and stepper drives, I/O and other functionality that conforms to the EtherCAT standard.

More Axes please!

The P600 has 2 built-in EtherCAT axes which can be user upgraded with the purchase of P912 Remote Axis FECs. Up to 64 axes are supported using CSP, CSV and CST modes of operation.

Each P912 doubles the available axes, i.e:

P600 + 1 x P912 = 4 Remote Axes

P600 + 2 x P912 = 8 Remote Axes

P600 + 3 x P912 = 16 Remote Axes

P600 + 4 x P912 = 32 Remote Axes

P600 + 5 x P912 = 64 Remote Axes

Of course, the Flex-6 Nano can be purchased with axes factory loaded ie:

P600 = 2 Axes

P601 = 4 Axes

P602 = 8 Axes

P603 = 16 Axes

P604 = 32 Axes

P605 = 64 Axes

So Fast, So Flexible

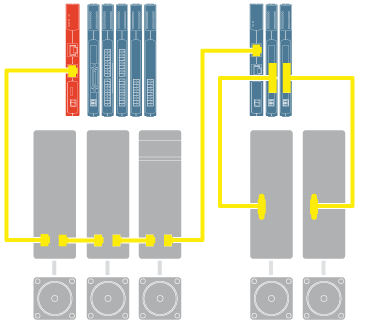

Trio’s Flexslice input/output modules provide a robust, high speed and flexible solution for both motion control and general automation. EtherCAT cycle times down to 125μsecs are supported and the bus coupler uses EBUS technology to bring all the sub-modules on to the EtherCAT network with no degradation in performance.

EtherCAT slave nodes (Flexslice Modules) are connected via the Flexslice EBUS and the EtherCAT connector. Total slave connections can be up to 128 nodes including I/O and complex devices.

Expanding the System

More "stations" (EtherCAT linked blocks of Flexslice Modules) can be added to the network using the second EtherCAT port on the P600 to connect to one or more P366 Flexslice Couplers.

Specification

Specification