MC664

in 2 variants

MC664 (-X)

P861 (Single Core) | P862 (Quad Core)

The MC664-X... Quad core A9 processor, Dedicated communications core, up to 128 axes and built-in EtherCAT port

all adds up to the most versitile Motion Coordinator yet!

Highlights

- Up to 128 Axes - 64 Stepper / Servo Axes and 64 Virtual Axes

- Precise 64 Bit Motion Calculations with Quad Core Cortex A9 1GHz Processor (P862)

- 4 GBit DDR3 Memory

- Dedicated Communications Core

- Built-in EtherCAT Port

- EtherCAT, Sercos, SLM and RTEX Digital Drive Interfaces

- Linear, Circular, Helical and Spherical Interpolation

- Flexible CAM shapes, Linked Motion

- EnDAT, BISS and SSI Absolute Encoder Supported

- Hardware Linked Outputs for Camera / Laser Control

- Ethernet-IP / Modbus TCP / Ethernet Interface Built-In

- Anybus-CC Module for Flexible Factory Comms Including ProfiNet/Profibus

- IEC 61131-3 Programming

- Multi-tasking BASIC Programming

- Text File Handling

- Robotic Transformations

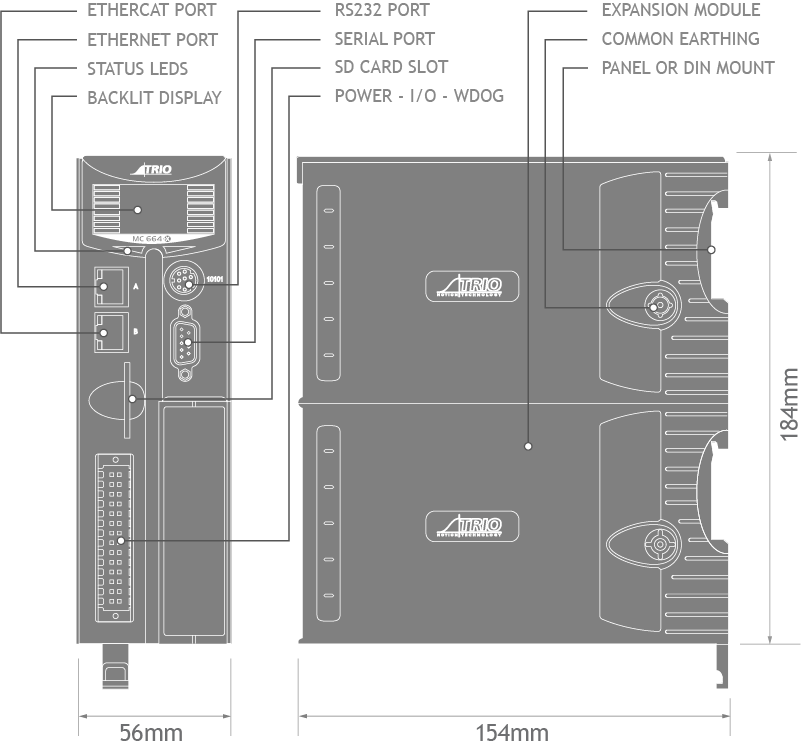

- SD Memory Card Slot

- CANopen I/O Expansion

- Backlit LCD Display

- RoHS and CE Approved

EtherCAT... So easy

The built-in Ethernet port allows programming and connection of common HMI and PLC protocols directly to the MC664.

EtherCAT axes can be upgraded with the purchase of the P914 Remote Axes FEC. The MC664-X is loaded with 2 EtherCAT axes out of the box, which can be upgraded also.

Each P914 doubles the available axes, i.e:

P862 + 1 x P914 = 4 Remote Axes

P862 + 2 x P914 = 8 Remote Axes

P862 + 3 x P914 = 16 Remote Axes

P862 + 4 x P914 = 32 Remote Axes

P862 + 5 x P914 = 64 Remote Axes

P862 + 6 x P914 = 128 Remote Axes

Every axis can be programmed to move using linear, circular or helical or spherical interpolation, electronic cams, linked axes and gearboxes. The quad core 1GHz processing power allows for multiple robotic transformations to run simultaneously.

User programs can be written in Trio’s established multi-tasking TrioBASIC language using the powerful Motion Perfect application development software making complex motion easy. Also available as an option are the industry standard IEC 61131-3 languages allowing a fully functional PLC programming system.

Ethernet

The built-in Ethernet port allows programming and connection of common HMI and PLC protocols directly to the MC664.

Easy to use

A bright easy to read backlit display enables the controller status to be easily determined.

So fast!

The MC664-x boasts quad-core processing power with a dedicated motion core and communications core allowing multiple robotc transformations to run simultaneously.

Both the MC664 single core and the MC664-X quad core models are ideal for high axis count machine and robotic applications.

Rugged

The single piece metal cast backplate provides an integrated earth chassis to improve noise rejection in the industrial environment.

So expandable

Configure the controller functionality and connectivity by attaching up to 7 half-height expansion modules or 3 full-height expansion modules. Using the expansion modules allows the MC664 to support up to 64 networked digital drives, 24 analogue servo drives, 25 pulse and direction drives and 25 absolute and incremental encoders.

The axis expansion modules feature many options for Drive Network interfaces, analogue servo, pulse/direction, absolute or incremental feedback and accurate hardware registration.

Specification

Specification