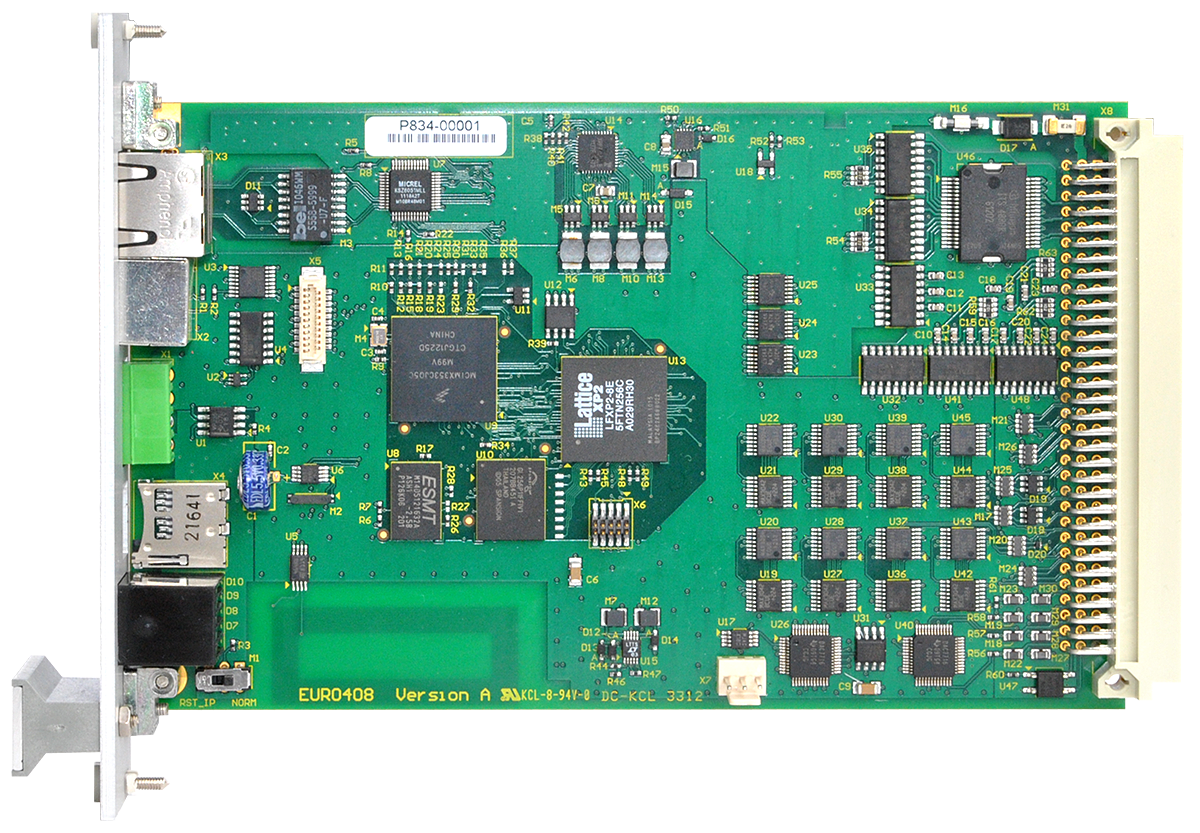

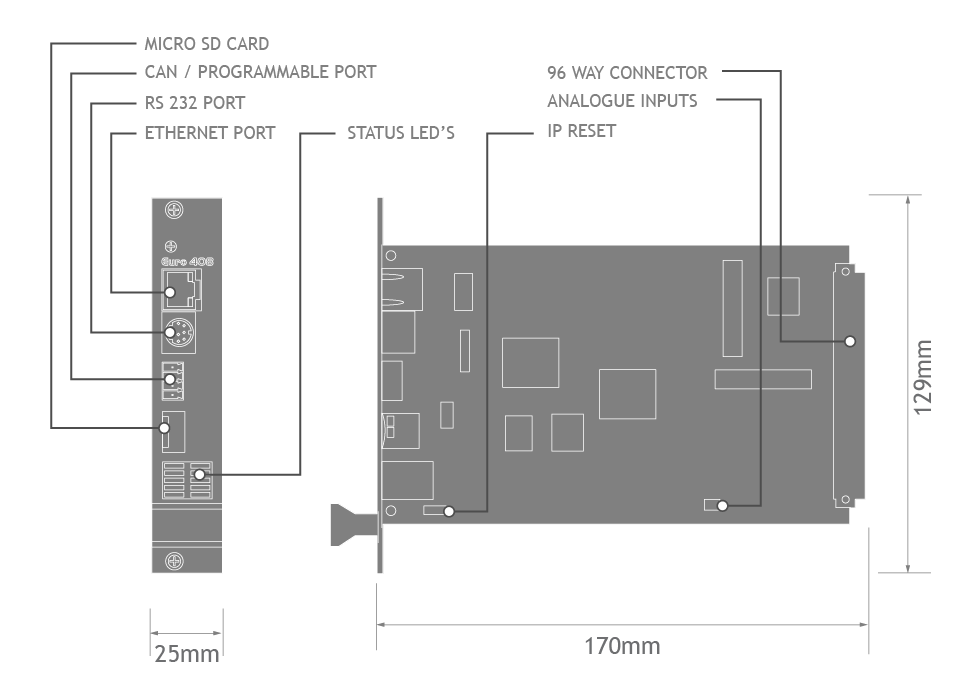

Euro404 / Euro408

P831 (Euro404) | P832 (Euro404 Servo) | P833 (Euro408) | P834 (Euro408 Servo)

The Euro404 and Euro408 Motion Coordinators are designed to provide a powerful yet cost effective control solution for OEM machine builders that are prepared to mount the unit and provide the power supplies required.

Highlights

- Linear, Circular, Helical and Spherical Interpolation

- Flexible CAM shapes, Linked Motion

- Biss, EnDAT and SSI Absolute Encoder Supported

- Hardware Linked Outputs for Camera / Laser Control

- Ethernet-IP / Modbus TCP / Ethernet Interface Built-In

- 125 – 2000 µsec Selectable Servo Update

- Precise 64 bit Motion Calculations on ARM11 Processor with VFP

- IEC 61131 Programming

- Multi-tasking BASIC Programming

- Text File Handling

- Robotic Transformations

- SD Memory Card Slot

- CANopen I/O Expansion

- 3U rack mount format

- RoHS approved

Connectivity

The flexible axis ports can be configured in software as feedback devices or pulse direction outputs. As outputs they can be used as pulse and direction with stepper or servo drives or they can operate as a simulated encoder output.

When configured as feedback they can be either incremental encoder input or one of three popular absolute encoder types; SSI, Tamagawa, Endat or Biss. Any feedback axis can be used with a voltage output to form a closed loop servo.

Expansion

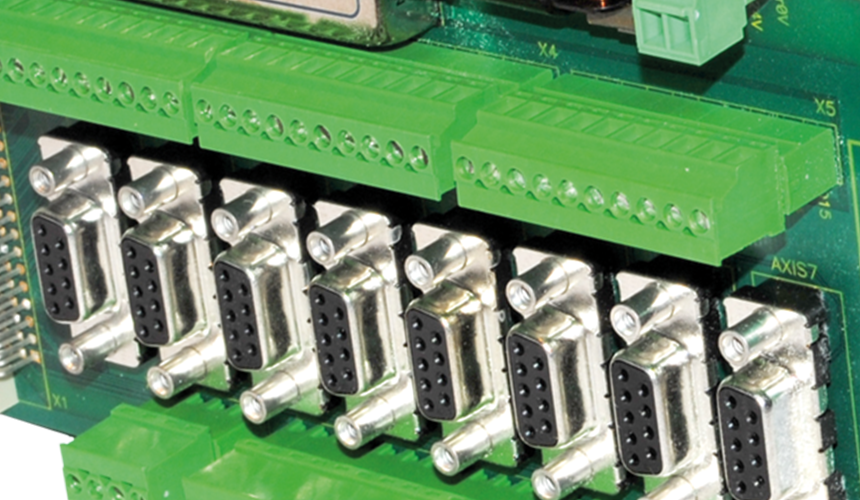

The P446 Breakout Board allows expansion via 8 9-way Dtype Flexible Axis connectors.

Flexibility

The Euro404 / 408 features a total of 16 axes in software. Any axes not assigned to built-in hardware can be used as a virtual axis. Every axis can be programmed to move using linear, circular or helical or spherical interpolation, electronic cams, linked axes and gearboxes.

|

|

|

|

|---|

| Product | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Description | 4 axis Eurocard motion coordinator | 4 axis Eurocard motion coordinator | 8 axis Eurocard motion coordinator | 8 axis Eurocard motion coordinator |

| Name | Euro404 | Euro404 | Euro408 | Euro408 |

| PCode | P831 | P832 | P833 | P834 |

| Status | Current | Current | Current | Current |

| Configuration | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Axis 0 | Core | Extended + AS | Core | Extended + AS |

| Axis 1 | Core | Extended + AS | Core | Extended + AS |

| Axis 2 | Core | Extended + AS | Core | Extended + AS |

| Axis 3 | Core | Extended + AS | Core | Extended + AS |

| Axis 4 | Core | Extended + AS | ||

| Axis 5 | Core | Extended + AS | ||

| Axis 6 | Core | Extended + AS | ||

| Axis 7 | Core | Extended + AS |

| Axes | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Max axes | 4 | 4 | 8 | 8 |

| Max networked axes | 0 | 0 | 0 | 0 |

| Max virtual axes | 16 | 16 | 16 | 16 |

| Max discrete wired axes | 4 | 4 | 8 | 8 |

| Performance | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Cores | 1 | 1 | 1 | 1 |

| Processor | ARM11 | ARM11 | ARM11 | ARM11 |

| Clock frequency | 532 MHz | 532 MHz | 532 MHz | 532 MHz |

| Maths precision | IEEE 457 Double | IEEE 457 Double | IEEE 457 Double | IEEE 457 Double |

| Position register precision | 64 bit | 64 bit | 64 bit | 64 bit |

| Execution benchmark | 35 lines/ms | 35 lines/ms | 35 lines/ms | 35 lines/ms |

| Real-time clock | Yes | Yes | Yes | Yes |

| Flash memory | 32 x 16000 values | 32 x 16000 values | 32 x 16000 values | 32 x 16000 values |

| User memory | 8 MB | 8 MB | 8 MB | 8 MB |

| Table memory | 512000 values | 512000 values | 512000 values | 512000 values |

| Min expected flash memory life (normal use) | 42 years | 42 years | 42 years | 42 years |

| Maximum VR variables | 4096 | 4096 | 4096 | 4096 |

| Maximum servo period | 2000 µs | 2000 µs | 2000 µs | 2000 µs |

| Minimum servo period | 125 µs | 125 µs | 125 µs | 125 µs |

| Maximum encoder input frequency | 6.000 MHz | 6.000 MHz | 6.000 MHz | 6.000 MHz |

| Maximum stepper output frequency | 2.000 MHz | 2.000 MHz | 2.000 MHz | 2.000 MHz |

| Drive interfaces | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Auxilliary axis | No | No | No | No |

| EtherCAT | No | No | No | No |

| Hydraulic | No | No | No | No |

| Piezo | No | No | No | No |

| Panasonic RTEX | No | No | No | No |

| SERCOS | No | No | No | No |

| Servo | No | Yes | No | Yes |

| SLM | No | No | No | No |

| Step & direction | Yes | Yes | Yes | Yes |

| Communications | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Anybus | No | No | No | No |

| Bluetooth | No | No | No | No |

| CANopen | Yes | Yes | Yes | Yes |

| CC-Link | No | No | No | No |

| DeviceNet | Yes | Yes | Yes | Yes |

| Ethernet | Yes | Yes | Yes | Yes |

| EthernetIP | Yes | Yes | Yes | Yes |

| Hostlink | Yes | Yes | Yes | Yes |

| MODBUS-RTU | Yes | Yes | Yes | Yes |

| MODBUS-TCP/IP | Yes | Yes | Yes | Yes |

| Profibus | No | No | No | No |

| ProfiNet | No | No | No | No |

| RS232/RS485 | Yes | Yes | Yes | Yes |

| USB 1.1 | No | No | No | No |

| Encoder ports | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Feedback input | Yes | Yes | Yes | Yes |

| Incremental (A+B) output | Yes | Yes | Yes | Yes |

| Pulse & direction output | Yes | Yes | Yes | Yes |

| Reference input | Yes | Yes | Yes | Yes |

| SSI Absolute Input | No | Yes | No | Yes |

| EnDat Absolute Input | No | Yes | No | Yes |

| Tamagawa Absolute Input | No | Yes | No | Yes |

| BiSS Absolute Input | No | Option | No | Yes |

| Internal I/O | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| +/-10V analogue outputs | 4 | 4 | 8 | 8 |

| Analogue output precision | 12 bits | 12 bits | 12 bits | 12 bits |

| Analogue Inputs (0-10V) | 2 | 2 | 2 | 2 |

| Analog input precision | 12 bits | 12 bits | 12 bits | 12 bits |

| Digital Bidirectional I/O (24V) | 0 | 0 | 0 | 0 |

| Digital Inputs (24Vdc) | 16 | 16 | 16 | 16 |

| Digital outputs (24Vdc) | 8 | 8 | 8 | 8 |

| Registration inputs | 8 | 8 | 8 | 8 |

| Registration speed | 20 µs | 20 µs | 20 µs | 20 µs |

| Watchdogs | 1 | 1 | 1 | 1 |

| Watchdog rating | 29V, 100mA max | 29V, 100mA max | 29V, 100mA max | 29V, 100mA max |

| External I/O | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| +/-10V analogue outputs | 16 | 16 | 16 | 16 |

| Analogue output precision | 12 bits | 12 bits | 12 bits | 12 bits |

| +/-10V analogue inputs | 32 | 32 | 32 | 32 |

| Analogue input precision | 12 bits | 12 bits | 12 bits | 12 bits |

| Digital I/O points | 512 | 512 | 512 | 512 |

| Programming | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Trio BASIC | Yes | Yes | Yes | Yes |

| DXF in | Yes | Yes | Yes | Yes |

| G-Code | Yes | Yes | Yes | Yes |

| HPGL | Yes | Yes | Yes | Yes |

| IEC61131 | Yes | Yes | Yes | Yes |

| Kinematic | Option | Option | Option | Option |

| Maximum programs | 32 | 32 | 64 | 64 |

| Maximum tasks | 10 | 10 | 22 | 22 |

| Software | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Motion Perfect version | 4 | 4 | 4 | 4 |

| Expansion | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Expansion module type | None | None | None | None |

| Maximum modules | 0 | 0 | 0 | 0 |

| Memory card | Micro SD | Micro SD | Micro SD | Micro SD |

| Physical | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Maximum operating temperature | 45 °C | 45 °C | 45 °C | 45 °C |

| Minimum operating temperature | 0 °C | 0 °C | 0 °C | 0 °C |

| Mount | Rack | Rack | Rack | Rack |

| Depth | 186.0 mm | 186.0 mm | 186.0 mm | 186.0 mm |

| Height | 128.0 mm | 128.0 mm | 128.0 mm | 128.0 mm |

| Width | 25.0 mm | 25.0 mm | 25.0 mm | 25.0 mm |

| Weight | 160 g | 160 g | 160 g | 160 g |

| Power | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| Supply current | 600 mA | 600 mA | 800 mA | 800 mA |

| Supply tolerance | 5% | 5% | 5% | 5% |

| Supply voltage | 5 V | 5 V | 5 V | 5 V |

| Certification | P831 Euro404 |

P832 Euro404 |

P833 Euro408 |

P834 Euro408 |

|---|---|---|---|---|

| CE | See note | See note | See note | See note |

| RoSH | Yes | Yes | Yes | Yes |

| UL |

| Note: CE Approval: All Eurocard products are designed for CE compliance as part of a system including power supply and interfaces. They are not tested for CE compliance by Trio. |

Axis Configuration Key

| Core functionality | |||

|---|---|---|---|

CORE AXES – can be configured in software as pulse and direction outputs with stepper or servo drives. They can also be configured for incremental encoder feedback. Core functionality is a set of ATYPEs (Axis TYPEs) that are available on all controllers. They are based on pulse outputs and incremental encoder feedback. |

|||

| ATYPE | Description | ||

| 43 | Pulse and direction output with enable output | ||

| 45 | Quadrature encoder output with enable output | ||

| 63 | Pulse and direction output with Z input | ||

| 64 | Quadrature encoder output with Z input | ||

| 76 | Incremental encoder with Z input | ||

| 78 | Pulse and direction with VFF_GAIN and enable output 1 | ||

| Extended functionality | |||

|---|---|---|---|

EXTENDED AXES – in addition to the Core functionality these axes can also be configured for absolute encoders and closed loop servos (requires voltage output). Only axes marked as AS have an analogue output and can be used for closed loop control. |

|||

| ATYPE | Description | ||

| 30 | Analogue feedback Servo | ||

| 44 | Incremental encoder Servo with Z input | ||

| 46 | Tamagawa absolute Servo | ||

| 47 | Endat absolute Servo | ||

| 48 | SSI absolute Servo | ||

| 60 | Pulse and direction feedback Servo with Z input | ||

| 77 | Incremental encoder Servo with enable output | ||

| 92 | Biss absolute servo | ||

| Products - Expansion |

|---|

Breakout Board (P446) The P446 Breakout Board allows expansion via 8 9-way D-type Flexible Axis connectors. |

| Products - CAN I/O Modules |

|---|

CAN I-O Expansion Modules Our range of digital and analogue input/output expansion modules are designed to enable simple and scalable and low-cost I/O extension for our Motion Coordinators. In addition to 24V input, output and bi-directional modules, there are relay and analogue I/O modules. |

| Products - Generic |

|---|

UNIPLAY 7-A UNIPLAY 10-A UNIPLAY 15-A Trio’s unique UNIPLAY HMI system is a revolutionary way to make operator interfaces better, easier and more secure! The UNIPLAY series boasts a 7", 10" and 15" colour displays. |

| Firmware - Euro404 | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Latest USER Release:

|

| Firmware - Euro408 | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Latest USER Release:

|

||||||||

| Software - Programming |

|---|

|

Motion Perfect Motion Perfect is designed to make setup, diagnostics, commissioning and using our range of Motion Coordinators as simple as possible. It provides the user with an easy to understand Windows based interface for rapid application development, controller configuration and monitoring of controller processes. |

|

IEC 61131-3 Runtime Software (P877) IEC 61131-3 standardises the programming language, the instruction sets and the handling and structuring of projects. As supplied, the IEC 61131 system will run programs for one hour after power-on, to allow engineers to try out their standard programs on the Motion Coordinator hardware. For continuous running, a software key (Feature Enable Code) can be downloaded from the Trio E-Store or purchased form your distributor for each Motion Coordinator to run IEC 61131 programs. . |

| Software - Upgrade Codes |

|---|

|

To upgrade the P831 to the P832 (Euro404), please log on to the E-Store and purchase: P835 upgrade code. |

|

To upgrade the P833 to the P834 (Euro408), please log on to the E-Store and purchase: P836 upgrade code. |

| Software - Expansion |

|---|

|

Kinematic Runtime FEC (P750) The P750 Robot kinematic runtime enables the more complex FRAME transformations which enable easy programming of various types of robot Including SCARA and Delta. (Log on to E-Store to purchase). |

| Software - Support Apps |

|---|

| Software Development Tools Trio has developed a set of powerful software development tools to use with every Motion Coordinator. These tools provide all the features necessary for setup, programming, cam profile generation, robot control and CAD path conversion to ensure a minimum development time. |

| Guides | |

|---|---|

| Data Sheet | |

| EMC Guide | Electromagnetic Compatibility guide for Trio products v6 |

| Certificates | |

|---|---|

| EU Declaration of Conformity | P831 + P833 |

| Manuals | |

|---|---|

| The Technical Reference Manual can be downloaded in full or as separate sections. All in PDF format. | |

| Hardware Overview (Chapter 2) | |

| Fieldbus Data | |

|---|---|

| EtherNet IP EDS (Electronic Data Sheet) files | Euro404 EtherNet IP EDS (Electronic Data Sheet) files |

| EtherNet IP EDS (Electronic Data Sheet) files | Euro408 EtherNet IP EDS (Electronic Data Sheet) files |

| DeviceNet EDS (Electronic Data Sheet) files | Euro404 DeviceNet EDS (Electronic Data Sheet) files |

| DeviceNet EDS (Electronic Data Sheet) files | Euro408 DeviceNet EDS (Electronic Data Sheet) files | Profinet GDSML | Profinet GDSML files |

| CAD Data | |

|---|---|

| Drawings are available in various formats These files are included in the Zip file below. | |

| Download Zip file | |

| Customer Help | |

|---|---|

| Customer Support Forum | Trio has a world-wide technical support network providing information to our Distributors, Solution Partners and Customers. This page includes a knowledge-base, user forum and direct online ticketing system where answers will be provided by our engineers in the UK, USA, India, China and Italy. |

| Training Courses | Our 2-day introductory courses are designed to provide an overview of the Motion Coordinator product range and to give an introduction to programming using the Motion-iX technologies. The course is based upon practical worked examples of each topic covered to enable the attendees to gain some valuable hands-on experience of using Motion Perfect to develop applications. |

| Product Repair Information | We offer a fixed price repair service via our distributor network. This page provides information on how to get your product repaired. |