MC6N-ECAT Mini Master

P960 (2 Axis) | P961 (4 Axis) | P962 (8 Axis) | P963 (16 Axis) | P964 (32 Axis) | P965 (64 Axis)

The MC6N is a high performance Motion Coordinator which is dedicated to running remote servo and stepper drives via the EtherCAT real time automation bus. It is based on the 1GHz i.MX7 Dual ARM Cortex A7 Core Processor which makes it ideal for high axis count machines or robotic applications.

Highlights

- EtherCAT Cycle Times Down to 125 µsec

- 1GHz i.MX7 Dual ARM Cortex A7 Core Process

- 1 GBit DDR3 Memory

- 128Mbyte Fast Serial NOR Flash

- Real Time Clock

- Up to 64 EtherCAT Digital Drive Axes

- Supports Position, Speed and Torque Drive Modes

- Up to 1024 EtherCAT I/O

- EtherCAT CoE protocol to CiA402

- Linear, Circular, Helical and Spherical Interpolation

- Flexible CAM shapes, Linked Motion

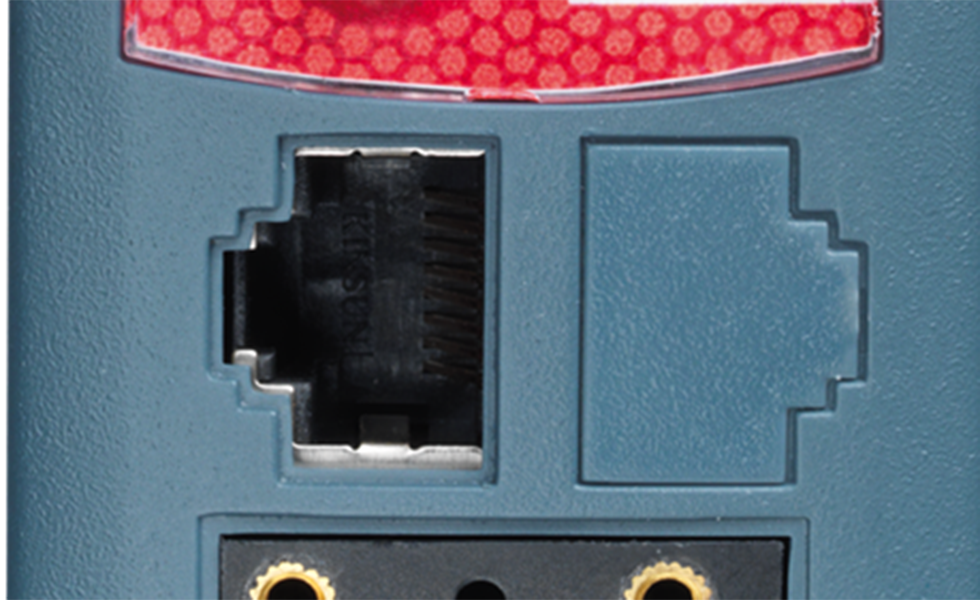

- Isolated Encoder Port

- Biss, EnDAT and SSI Absolute Encoder Supported

- Hardware Linked Output for Camera / Laser Control

- Ethernet-IP / Modbus TCP / Trio ActiveX / Uniplay HMI / UDP / Ethernet Interface Built-In

- IEC 61131-3 Programming

- Multi-tasking BASIC Programming

- Text File Handling

- Robotic Transformations

- 4 high speed registration inputs

- Isolated RS232 and RS485 ports

- SD Memory Card Slot

- EtherCAT I/O Expansion

- CANopen I/O Expansion

- Backlit LCD Display

- RoHS and CE Approved

Plug and Play

The MC6N supports up to 64 axes of motion with 64 bit integer position registers for ultra precise axis resolution.

EtherCAT slave drives and I/O can be connected and run in cyclic synchronous position, speed or torque modes provided these are supported by the drive.

EtherCAT

The P960 has 2 built-in EtherCAT axes which can be user upgraded with the purchase of P912 Remote Axis FECs.

Each P912 doubles the available axes, i.e:

P960 + 1 x P912 = 4 Remote Axes

P960 + 2 x P912 = 8 Remote Axes

P960 + 3 x P912 = 16 Remote Axes

P960 + 4 x P912 = 32 Remote Axes

P960 + 5 x P912 = 64 Remote Axes

Of course, the MC6N can be purchaced with axes factory loaded ie:

P960 = 2 Axes

P961 = 4 Axes

P962 = 8 Axes

P963 = 16 Axes

P964 = 32 Axes

P965 = 64 Axes

Every axis can be programmed to move using linear, circular or helical or spherical interpolation, electronic cams, linked axes and gearboxes. The power of the controller allows for multiple robotic transformations to run simultaneously.

Easy to use

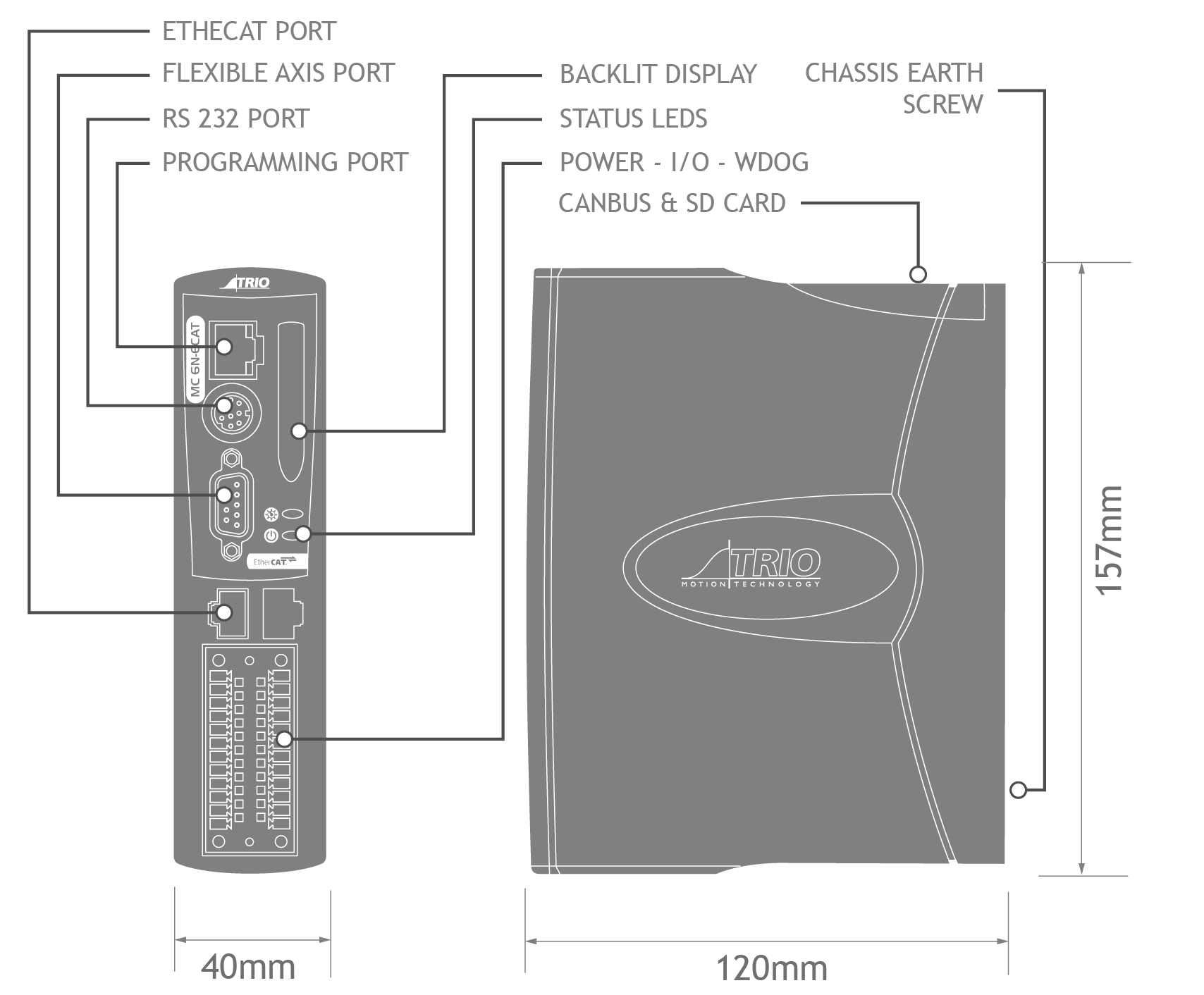

A bright easy to read backlit display enables the controller status to be easily determined, whilst the single piece metal cast backplate provides an integrated earth chassis to improve noise rejection in the industrial environment.

Familiar Tools

The built-in Ethernet port allows programming and connection of common PLC and HMI protocols, including the Trio Uniplay range of HMIs, directly to the MC6N. User programs can be written in Trio’s established multi-tasking TrioBASIC language using the powerful Motion Perfect application development software making complex motion easy. The industry standard IEC 61131-3 languages are available as an option, allowing a fully functional PLC programming system.

Specification

Specification